How Prototyping Helps You Save Costs, Production Time, and the Environment

One vital part of developing your medical device and preparing it for assembly is prototyping. At Technobis, we have the in-house facilities and expertise for running preliminary tests, to speed up the overall rollout and time-to-market of your health technology products. It also helps you reduce your carbon emissions and costs, as we no longer have to transport parts back and forth between prototyping partners. Read on to find out more about Technobis’ medical device prototyping process.

What is prototyping?

Simply put, prototyping means test building components and final products. It is a vital part of our product development process. Prototyping involves building a test version of a proposed design to check its feasibility, whether it works as planned, and to detect and tackle any unforeseen problems At Technobis, we distinguish between sub-level and main level prototyping.

Sub-level prototyping

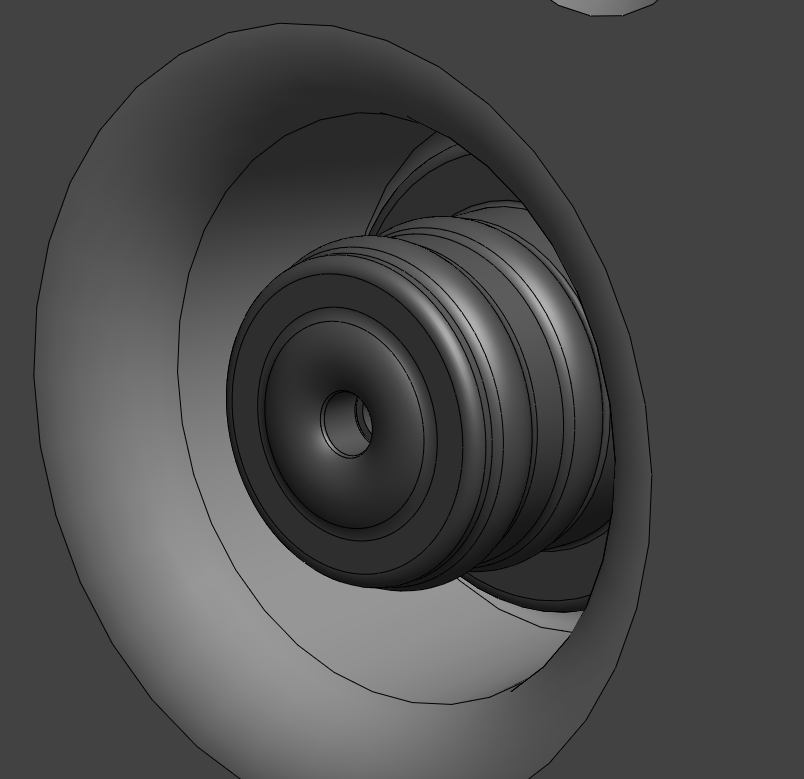

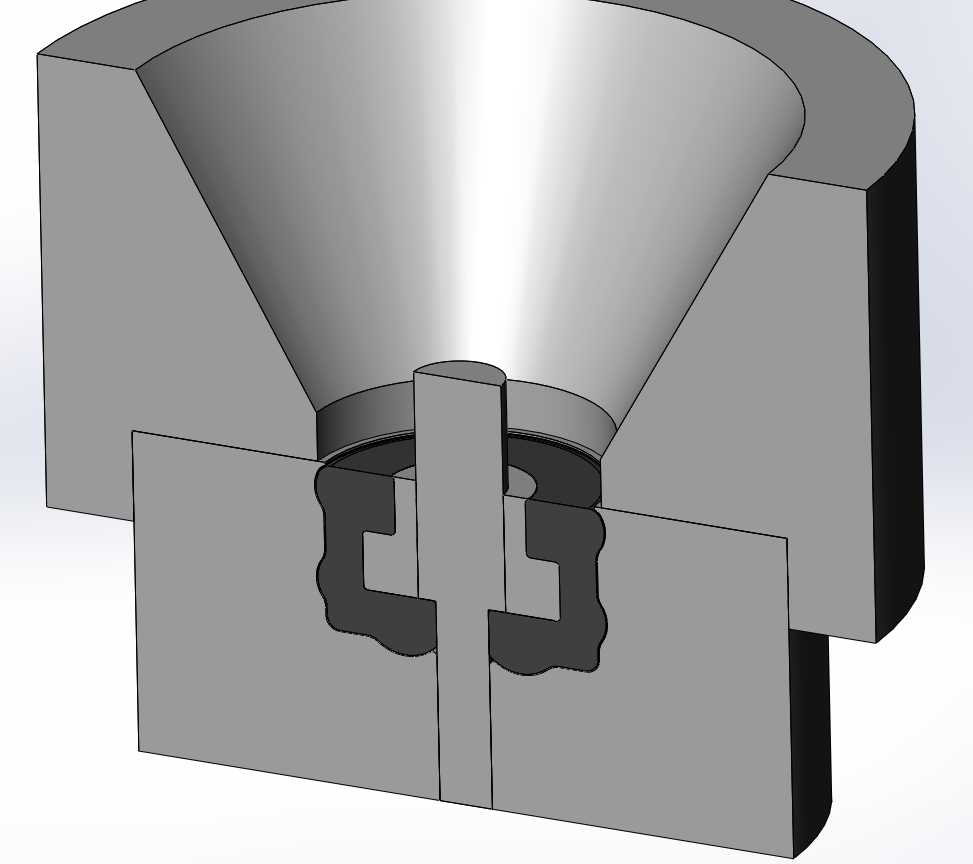

Sub-level prototyping is an essential part of our initial design stages, and an iterative process. As your medical device may be a completely new instrument, our engineers must design specific complex parts that solve specific problems, and have not been developed before.

To make sure that their ideas work as planned and that they work both sustainably and cost-effectively, our engineers can develop complex parts of their design by using our workshop facilities or with the help of our partners. It allows them to test components’ properties and if needed, make design adjustments. For instance, we can quickly fine-tune physical parameters such as surface roughness, geometry, tolerances and strength. This stage mitigates the number of variables in the next prototyping phase.

3D-render of sub-level component part design proposal. (Technobis.com)

Cross-section of a sub-level component part design proposal. (Technobis.com)

Main-level prototyping

In this stage, we test your product in its pre-production form. Our engineers create a fully functional model of an issued medical device, to see if the sub-level features work together according your desired specifications. Whether it works as requested, and if the design can still be improved.

Importance of prototyping for the medical industry

Prototyping is essential in creating health technology equipment that can be relied on during medical procedures. Functionalities must be 100% accurate, as minor deviations from the required norms can potentially elicit fatal results. Combined with our robust quality management systems, prototyping offers you the guarantee that every component of your design has been thoroughly thought out and is the result of multiple iterations. Additionally, prototyping helps you secure proof that every part of the design works according to pre-set requirements, and can make a difference in clinical trials.

Benefits and advantages of in-house prototyping processes

Having in-house prototyping facilities allows our engineering and design teams to quickly visualise and improve on ideas. This greatly speeds up the design process. By running a preliminary component part design through our 3D printer, we can test whether the part works as planned. By doing this in-house, we eliminate the time of sending it to an external party, where it may end up in a queue and can take weeks to be shipped back to us. By taking out the transportation stage, we additionally help you reduce your CO2 footprint. It also helps you save on external prototyping costs.

Another major advantage of overseeing our own prototyping is that we control how prototype parts are subjected to regulatory testing, and whether your end product adheres to our safety and quality procedures. By making prototyping part of our own thorough development process, your product will meet requirements for validation and certification procedures, and performs as expected during clinical tests.

In short, our prototyping helps your finished product hit the market faster, reduce costs and carbon emissions, and better adhere to predefined specifications.

Prototyping and intellectual property

As the engineering team of Technobis develops fresh ideas for new medical-grade equipment, some emerging solutions must be documented and patented. At Technobis, we regard this as a service to our clients. Ownership of intellectual property lies solely with our clients. Technobis aims to offer stellar service when it comes to the whole chain of development, certification support, testing, and production of equipment for the BioTech, MedTech and PharmaTech industries. We will of course compile all the necessary documentation to help you apply for patents.

Technobis Prototyping: towards full-scale manufacturing

In a nutshell, prototyping is essential for sustainably developing ground-breaking high-grade medical equipment. It helps us determine the feasibility and accuracy of features that are necessary to operate a new medical instrument in accordance with its predefined specifications. By testing them beforehand and documenting feasible evidence, prototyping is a tool that helps your device through various validation and certification stages.

3D-printed Prototype of a proposed component part allows engineers to test the feasibility of an idea. (Technobis.com)