How Technobis Uses Value Engineering to Improve Your Competitive Edge

If you choose to work with Technobis, you will benefit from our value engineering qualities. We do not just offer a one-off service of helping you get your final product released, we continue to look at optimising your products and processes throughout production. Value engineering is part of Technobis’ DNA, and is strictly a team approach. In theory, cost price reductions of as much as 30% are possible through our ve process. Here’s how it works.

Whenever you decide to work with us and let us produce your product in serial production, the first aim is to help you get started. In other words, we help you make a working product. Once established, you will experience a level of growth within your company, propelling you into the competitive realm.

Reducing Costs for Raw Materials and Methods

As demand grows, you will need to upscale your project production, and reduce costs to maintain a competitive edge. It is an economic given that once sales numbers increase, your prices will have to drop. This means a smaller profit margin for you. To counter this effect, you may need to find ways to lower production costs. One of the answers is Value Engineering. At Technobis, this is strictly an organised effort.

There are multiple ways to go about value engineering. In short, we can help you find solid alternatives to reduce costs in various aspects of production without sacrificing functionality, as well as in the choice of materials and the testing phases. We do this through thorough information gathering and value analysis.

Production Cost Reduction

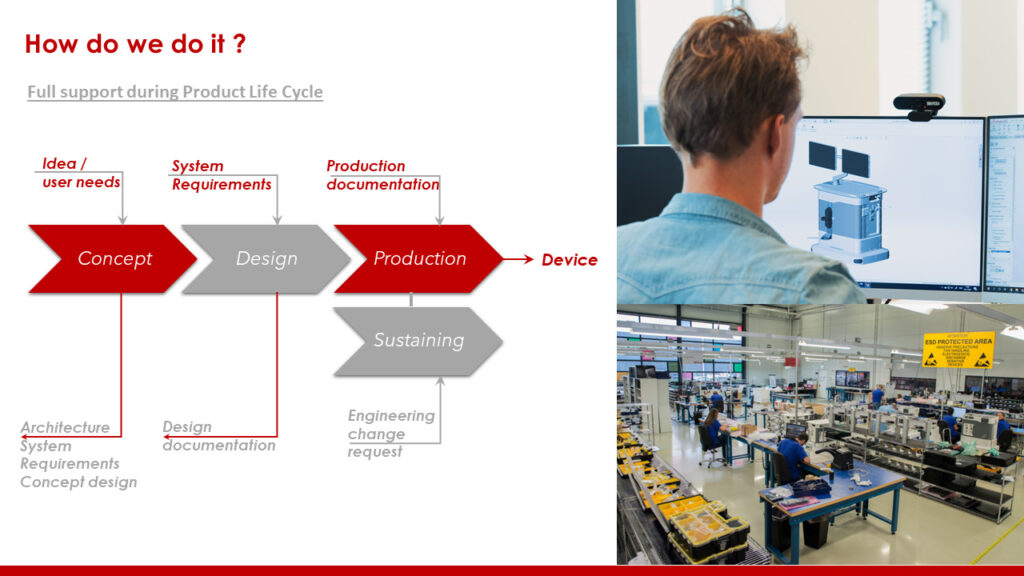

At Technobis, we are committed to production cost reduction. Throughout the planning stage, development phase, design phase, and first assembly tests for your product, we assess possible ways to improve production efficiency in the future. These are recorded in the documentation we provide. In the first phases of production, however, it is key to simply start production and create a working product that serves the interests of your first clients. Value engineering can wait for future rising numbers.

Finding Alternative Materials

and Reducing Unnecessary Costs

When that day comes, we will first make an analysis of your product’s raw materials, and see if we can find cheaper alternatives without compromising our high quality standards and your product’s unique properties. For instance, one of our clients created a product that included platinum conductors. After thorough research, it turned out that they could easily be replaced by stainless steel conductors. As these component parts were more readily available at a fraction of the price, this created a considerable annual price reduction.

Technobis maintains good relations with various suppliers, and part of our expertise is in our ability renegotiate prices.

Reassessing Your Design

To further reduce costs for your production process, our design team may reenter the creative phase, and take a second look atthe schematic stage, design and layout of your product. Quite often, it is possible to find redundant features, or more optimal component constellations that make your products quicker, easier and more cost effective to assemble, which helps us save valuable time and money. Sometimes, it is as simple as adding a loop or hook to various components, to help a robot pick it up and assemble it easier and ramp up your production speed.

Evaluating Your Components

A second option for improving ease of production is our component evaluation phase, in which we combine separate parts into custom component parts. These can be engineered to be 3D printed or formed through injection moulding or die casting. Instead of having to attach various parts one after the other, our assembly line can then simply add one block that includes several parts at once. This quite literally saves time on fastening and adjusting screws and bolts.

Similarly, your initial production stages may still involve manual soldering, which means a suboptimal cost-price parameter. We can re-examine your product to see whether it may be viable to develop custom cable bundles or wiring harnesses, which are easier to connect and save a lot of time and energy, and greatly improve the systematic process.

This is most feasible if your product reaches the status of a well-established industry standard, as custom component production will mean setting up another production line specifically for your product.

Providing Rationales and Further Documentation

Value Engineering within a medical context has the added challenge of mandatory re-certification. A costly ordeal, which requires thorough feasibility research beforehand.

If you set out to alter a previously certified medical device, you must be able to explain to the certification agencies why your proposed change would be an improvement, and prove how it will have the same or better functionality and safety aspects. When we evaluate ideas and set out to improve your products’ pricing through value engineering, we also take this into consideration. We will help you provide the required documentation in the form of a rationale, detailing why the change is necessary, and how it will be done.

Product Tear-Down Sessions

Of course, we do not set out our value engineering process without your consent. To involve your value engineering team in the value engineering process, we can arrange Product Tear-Down sessions or workshops. In those, our combined teams come together to literally pick your product apart piece by piece. In this function analysis, we can then assess all aspects and component parts of your product separately. We discuss its basic function, chart both redundant functions and necessary functions, and see how we can improve its design, its physical attributes, acceptable substitutes, production processes, and life cycle costs, or find cost-effective alternative solutions. All involved are welcome to chip in with their creative ideas, to maximize function and find possible solutions to improve quality for your final product.

Sample Testing

Once your final product’s basic functions have been thoroughly tested and certified, there is no need to maintain the same level of scrutiny during production. In other words, we no longer have to test each produced unit separately. We can then opt to start sample testing, where we pick out one unit per produced batch, instead of testing the whole batch. This helps you save tremendously on testing costs, and speeds up your Time to Market.

Software Value Analysis

One way of adding value to your existing products is by reassessing their software and essential functions, improving performance, and expanding their functionalities to offer greater customer value. In some cases, your product may have been in production for several years, and may simply need an update for commercial purposes. An update can give you a reason to reach out to former buyers, and convince them to reinvest.

At Technobis, we take great pride having value engineering at the very core of our activities. From the initial sketches to annual reviews, we can help you establish cost savings, and increase your competitive standing.

If you want to discuss your ideas or products in terms of value engineering, do not hesitate to reach out to us today.