From Concept to Series Production in Just 3 Months!

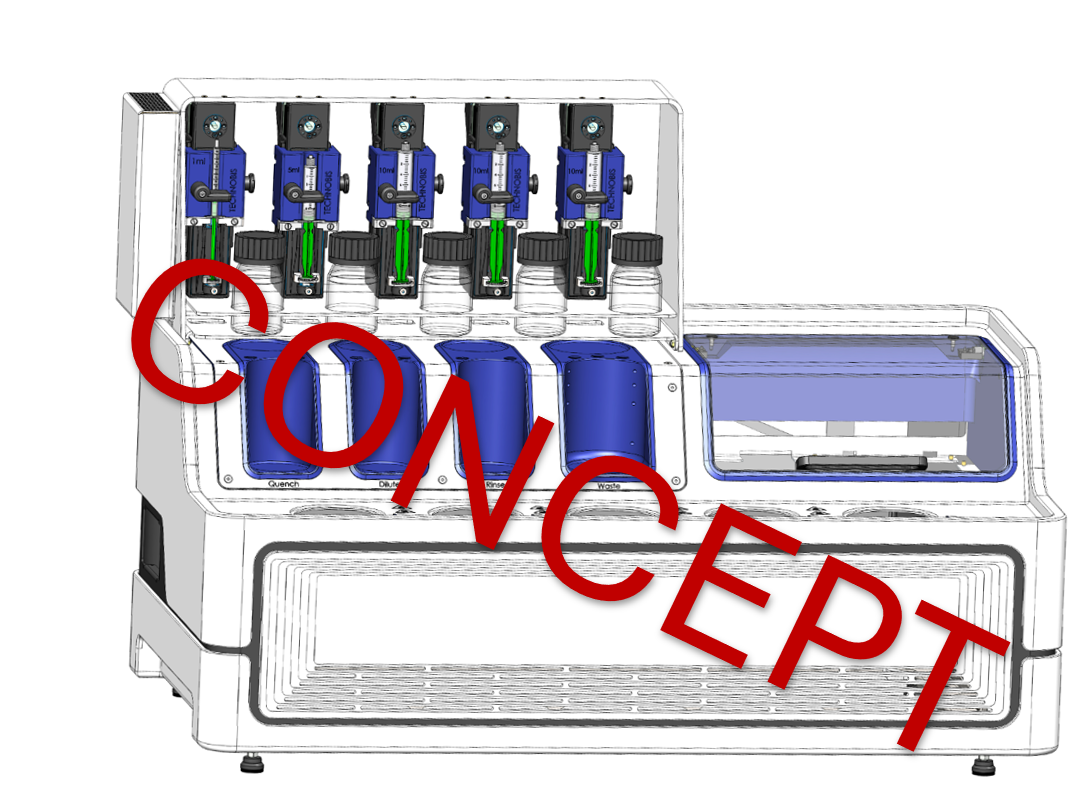

At Technobis Hightech Solutions, we thrive on transforming bold ideas into reality — fast. After the summer break, our sister company, Technobis, approached us with a thrilling challenge: develop a Dosing Module add-on for the ReactAll platform and have Beta systems ready before Christmas. The timeline was ambitious, but with the right mindset and expertise, we knew we could deliver.

A Multidisciplinary Powerhouse

This project put our multidisciplinary capabilities to the test, and our team rose to the challenge. Here’s how we brought the concept to life:

🔹 Requirements Gathering and Risk Analysis

Before diving into design, we conducted requirements workshops to capture the functional and technical needs of the dosing module. Our engineers worked closely with stakeholders to define clear performance criteria and use cases. To ensure the project’s success and mitigate potential pitfalls, we also performed comprehensive risk analyses. By proactively identifying and addressing possible risks — from design limitations to supply chain disruptions — we built a solid foundation for rapid development.

🔹 Embracing the MVP Mindset

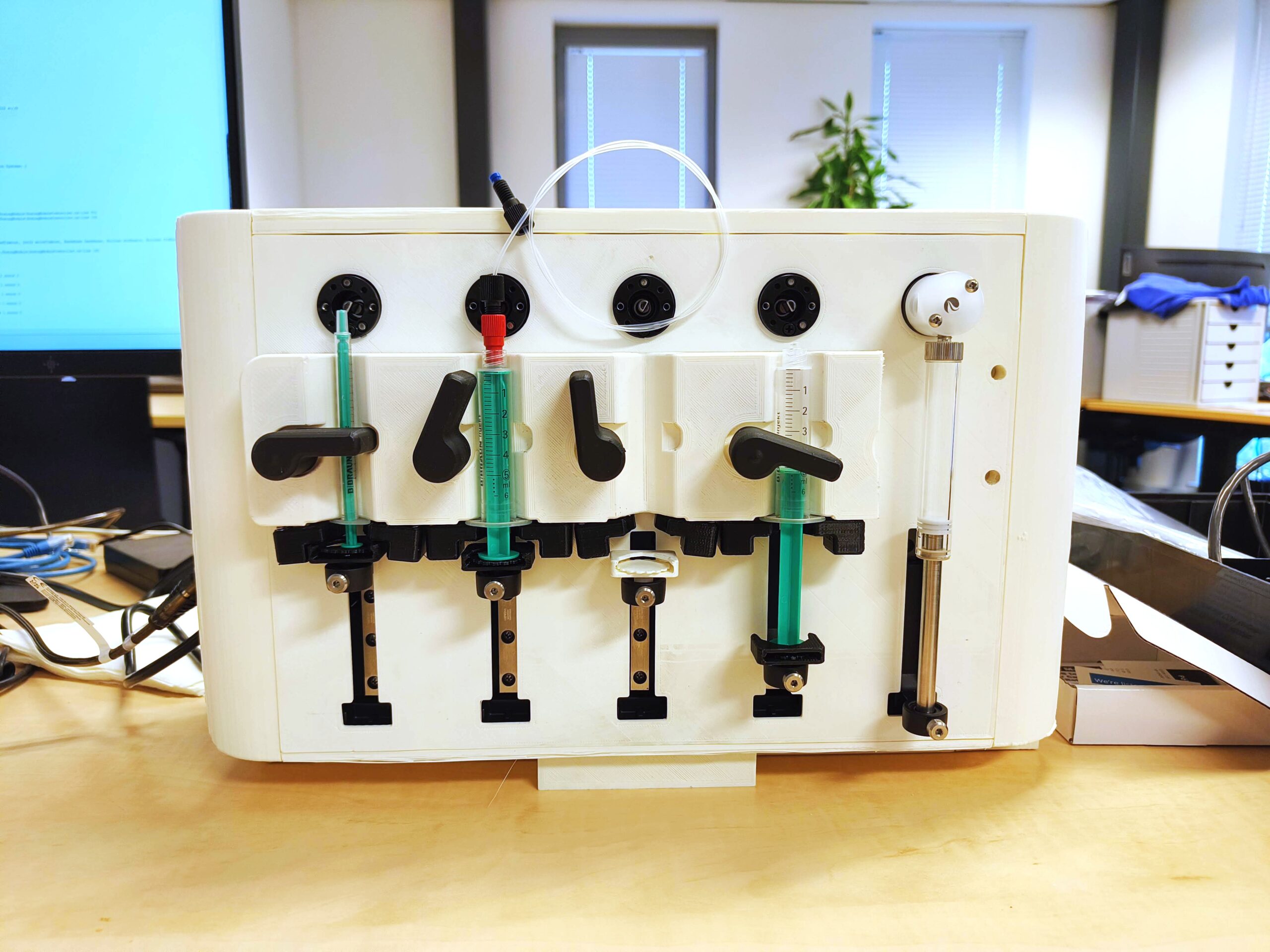

A key part of our approach was the creation of an MVP (Minimum Viable Product). An MVP focuses on the core functionalities needed to validate an idea quickly, gather feedback, and refine it further. By identifying the critical features of the dosing module and prioritizing them, we could streamline development and ensure we delivered real value to the users — without unnecessary delays. This approach enabled rapid iteration and early testing, paving the way for a successful Beta launch.

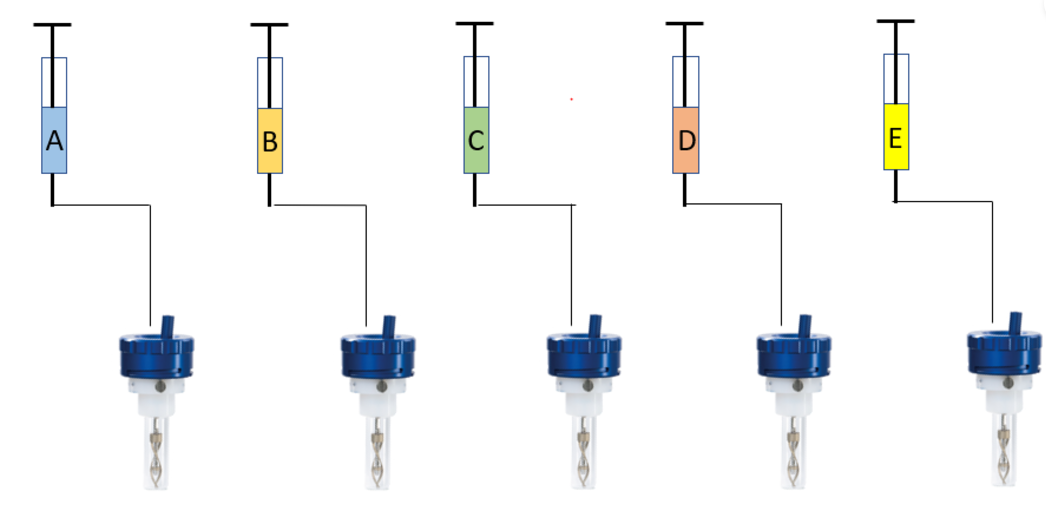

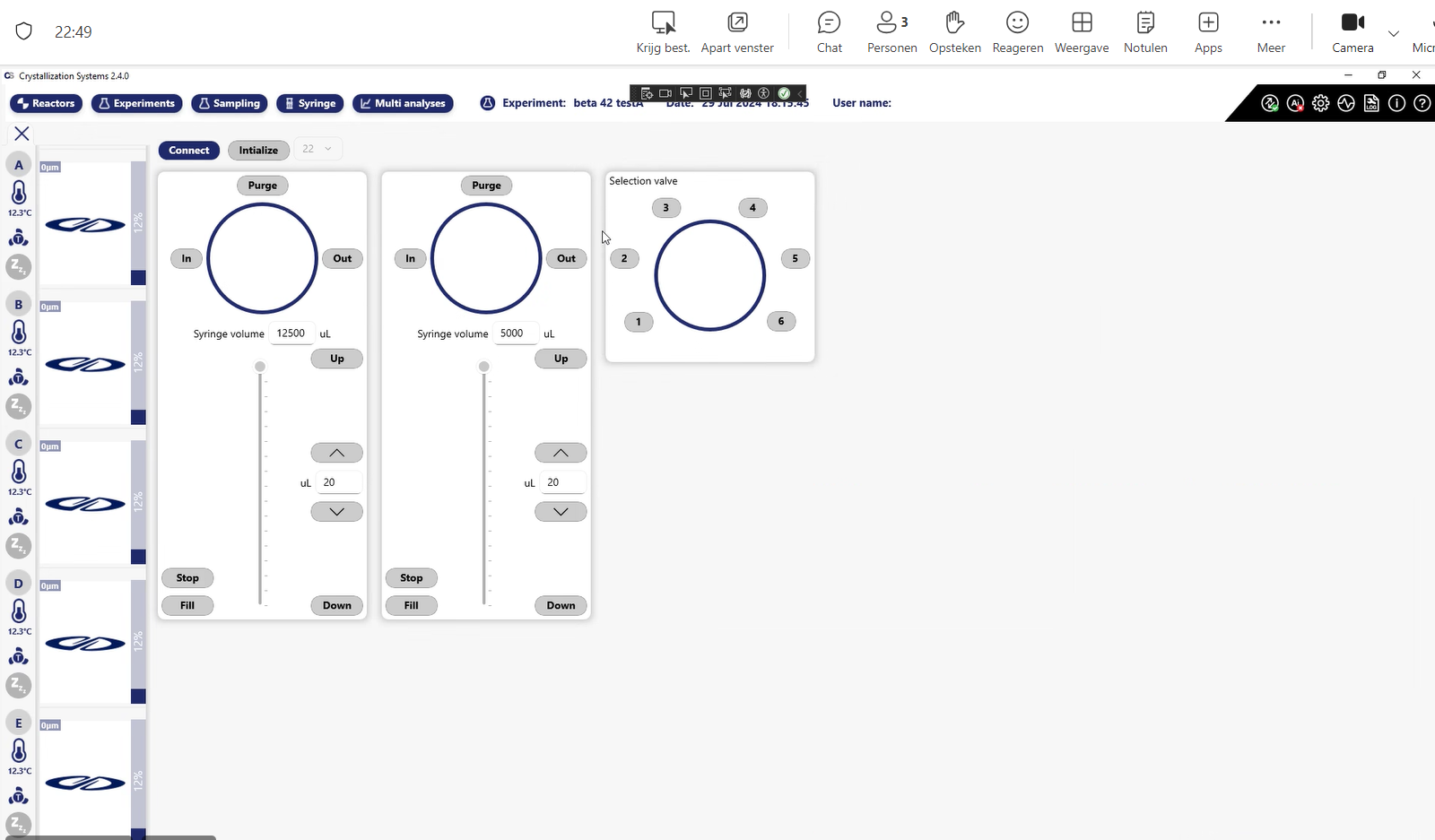

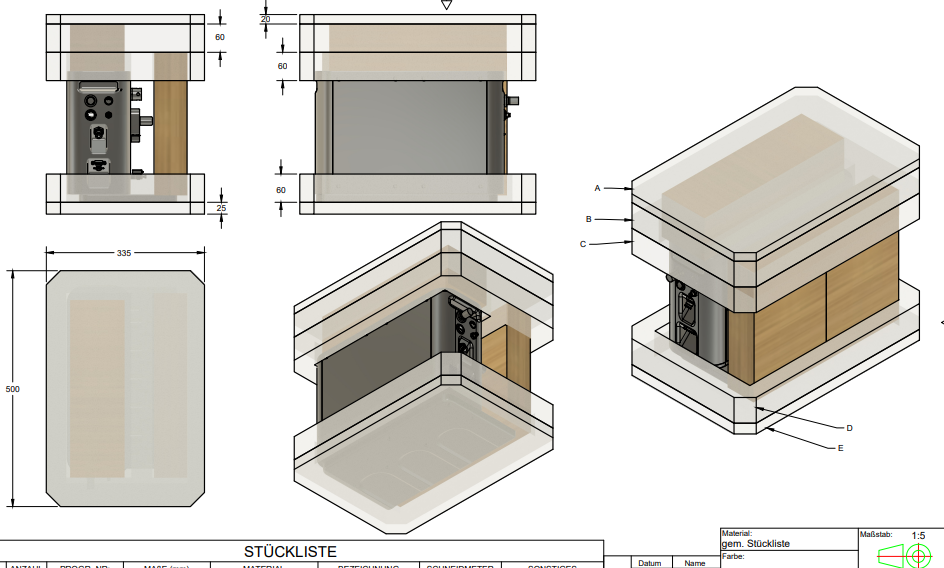

🔹 Software and Mechanical Prototyping

Armed with a clear understanding of the requirements and the MVP definition, we launched mechanical and software prototyping in parallel. Our software engineers focused on developing the control algorithms and intuitive user interfaces, while our mechanical team engineered a robust and reliable dosing mechanism tailored to the ReactAll platform. This iterative approach — combining digital and mechanical design — allowed us to refine the MVP quickly and ensure seamless system integration.

🔹 Cable Development

Reliable connectivity was crucial for the dosing module’s performance. Our cable development specialists designed and assembled custom cable harnesses, ensuring robust data and power connections to support the precise dosing operation.

🔹 Sourcing and Procurement

To turn our MVP prototypes into functional Beta systems under tight deadlines, our sourcing and procurement team leveraged their global network to secure essential components swiftly. Balancing lead times, quality, and cost, they kept the project moving without delays — even in the face of challenging market conditions.

🔹 Supply Chain Management and Quality Control

Our supply chain management experts coordinated deliveries, tracked shipments, and proactively addressed any supply bottlenecks. Meanwhile, our quality control team meticulously inspected every part and assembly, upholding the high standards that define Technobis Hightech Solutions.

🔹 Certification Support: Requirements and Risk-Driven

Bringing high-tech solutions to market means ensuring they meet stringent industry standards. Our certification support team was actively involved throughout the project, integrating requirements and risk analysis into every stage. They ensured that designs met regulatory frameworks, documented critical steps, and supported the creation of risk management files. This attention to detail was essential to prepare the Beta systems for compliant operation and further validation.

🔹 Assembly and Testing

With everything in place, our skilled assembly and testing teams brought the dosing module to life. They meticulously assembled each unit, conducted rigorous functional testing, and verified performance under real-world conditions — ensuring the MVP wasn’t just a prototype, but a fully operational Beta system.

Collaboration and Commitment

This project’s success hinged on seamless collaboration. Our journey began with a full-team kick-off on September 26th, setting clear milestones and communication lines. With weekly project meetings and a unified goal, our team maintained momentum and worked together to solve challenges as they emerged.

In just three months, we transformed a concept into a fully functional MVP and then took it further to a Beta series production — a testament to the power of collaboration, technical excellence, and shared commitment.

Ready to Innovate with Us?

At Technobis Hightech Solutions, we’re passionate about turning ambitious ideas into real-world solutions. From prototyping and risk-driven design to certification-ready systems and series production, we’re here to bring your next innovation to life.

Contact us for more information.